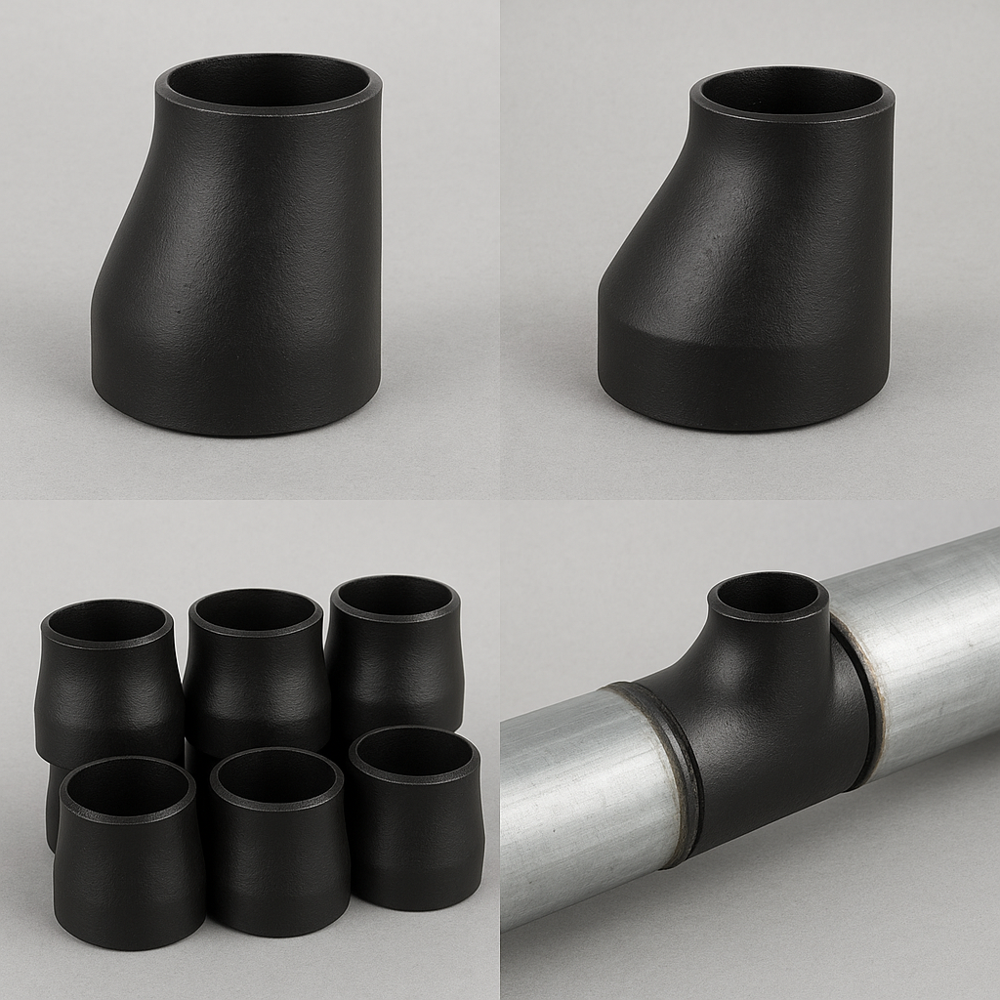

MS ERW B-Class Reducer

Price 55.0 INR/ Piece

MOQ : 1 Piece

MS ERW B-Class Reducer Specification

- Surface Finish

- Smooth

- Features

- Good Quality

- Usage

- Industrial

- Material

- MS

- Corrosion Resistant

- Yes

- Shape

- Reducing

- Color

- Black

- Warranty

- Yes

MS ERW B-Class Reducer Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- nhava sheva

- Payment Terms

- Cheque, Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA), Paypal

- Supply Ability

- 2 Pieces Per Day

- Delivery Time

- 3 Days

- Sample Available

- No

- Sample Policy

- Within a certain price range free samples are available

- Main Export Market(s)

- Australia, Asia, North America, Middle East, Africa, South America, Eastern Europe, Western Europe, Central America

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015, PED Approved, Mill Test Certificate (MTC), Third-Party Inspection (TPI)

About MS ERW B-Class Reducer

MS ERW B-Class Reducers are fabricated from Mild Steel Electric Resistance Welded (ERW) pipes in accordance with IS1239 standards (medium duty). These fittings are used to reduce the bore size of a pipeline, ensuring smooth flow transition while minimizing turbulence. Induskart offers both concentric and eccentric reducers in MS ERW B-Class, making them suitable for medium-pressure pipelines in water, gas, HVAC, and industrial applications.

Technical Specifications:

Material Grade: Mild Steel IS1239 B-Class (Medium Duty)

Type: Concentric & Eccentric Reducers

Standard: IS1239 / IS3589

Size Range: 1 x to 12 x 6 NB

Thickness Class: B-Class (Medium Duty)

Manufacturing Method: ERW Pipe Formed & Buttweld Fabricated

Surface Finish: Black Painted, Anti-Rust Oiled, Galvanized (optional)

End Type: Beveled Ends for Welding

Testing: Hydrostatic Test, Dimensional & Visual Inspection

Certifications:

ISO 9001: 2015, IS1239 Certified, MTC available, TPI approved

Applications & Buyer Types:

Water Supply & Distribution Networks

Gas Pipelines

Firefighting & HVAC Systems

Agricultural Irrigation Pipelines

Industrial & Structural Piping Works

Buyers include EPC contractors, OEMs, builders, municipal bodies, and maintenance engineers

FAQ:

What is the difference between concentric and eccentric reducers?

Concentric reducers maintain pipe centerline, eccentric reducers offset one side.

Why B-Class specification?

B-Class means medium-duty thickness suitable for general water and gas pipelines.

Are galvanized reducers available?

Yes, galvanized reducers are supplied on request.

What sizes can you supply?

Standard from 1 x to 12 x 6, with custom options available.

Call to Action:

Ensure smooth and durable pipe transitions with Induskarts MS ERW B-Class Reducers. Contact us today for bulk supply, customized dimensions, and technical support.

Technical Specifications:

Material Grade: Mild Steel IS1239 B-Class (Medium Duty)

Type: Concentric & Eccentric Reducers

Standard: IS1239 / IS3589

Size Range: 1 x to 12 x 6 NB

Thickness Class: B-Class (Medium Duty)

Manufacturing Method: ERW Pipe Formed & Buttweld Fabricated

Surface Finish: Black Painted, Anti-Rust Oiled, Galvanized (optional)

End Type: Beveled Ends for Welding

Testing: Hydrostatic Test, Dimensional & Visual Inspection

Certifications:

ISO 9001: 2015, IS1239 Certified, MTC available, TPI approved

Applications & Buyer Types:

Water Supply & Distribution Networks

Gas Pipelines

Firefighting & HVAC Systems

Agricultural Irrigation Pipelines

Industrial & Structural Piping Works

Buyers include EPC contractors, OEMs, builders, municipal bodies, and maintenance engineers

FAQ:

What is the difference between concentric and eccentric reducers?

Concentric reducers maintain pipe centerline, eccentric reducers offset one side.

Why B-Class specification?

B-Class means medium-duty thickness suitable for general water and gas pipelines.

Are galvanized reducers available?

Yes, galvanized reducers are supplied on request.

What sizes can you supply?

Standard from 1 x to 12 x 6, with custom options available.

Call to Action:

Ensure smooth and durable pipe transitions with Induskarts MS ERW B-Class Reducers. Contact us today for bulk supply, customized dimensions, and technical support.

Precision Engineering for Industrial Use

Manufactured from premium mild steel, the MS ERW B-Class Reducer is engineered for demanding industrial environments. Its smooth surface finish and black color not only enhance its appearance but also add to its resistance against corrosion, ensuring stable operations in fluid and gas piping systems.

Supplier and Trader Network Across India

As a trusted supplier and trader in India, we ensure each MS ERW B-Class Reducer is meticulously checked for quality. With prompt distribution channels, industrial clients can receive timely deliveries for maintenance and new installations, fostering efficient operations.

FAQs of MS ERW B-Class Reducer:

Q: How is the MS ERW B-Class Reducer used in industrial settings?

A: The reducer is primarily used to connect pipes of varying diameters within industrial piping systems. It enables efficient fluid or gas transfer and minimizes the risk of pressure loss due to mismatched pipe sizes.Q: What materials are used to manufacture the MS ERW B-Class Reducer?

A: This reducer is made from high-grade mild steel (MS), which offers excellent durability and inherent resistance to corrosion, making it ideal for industrial applications.Q: When should you choose a reducing shape reducer for your system?

A: A reducing shape reducer should be chosen when theres a need to join pipes of different diameters, especially to ensure a smooth and secure transition in fluid or gas pipelines.Q: Where can I purchase the MS ERW B-Class Reducer in India?

A: MS ERW B-Class Reducers are readily supplied and traded by reputable distributors and suppliers throughout India. You can contact us for availability and prompt delivery.Q: What is the warranty and what does it cover?

A: The MS ERW B-Class Reducer comes with a warranty, which typically covers manufacturing defects or faults in material quality, offering added assurance to industrial users.Q: How does the corrosion-resistant feature benefit users?

A: The corrosion-resistant property significantly extends the reducers lifespan and maintains the integrity of your piping system, even when exposed to harsh industrial environments.Q: What process is used to ensure product quality?

A: Each reducer undergoes strict quality inspections for material integrity, finish, and dimensional accuracy, ensuring that it meets industry standards for performance and reliability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pipe Fitting Category

MS ERW B-Class Equal Tee

Price 320.0 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Surface Finish : Smooth

Material : MS

Color : Black

MS ERW B Class 45 Short Radius Elbow

Price 278.0 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Surface Finish : Smooth

Material : MS

Color : Black

MS ERW B-Class Reducing Tee

Price 350.0 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Surface Finish : Smooth

Material : MS

Color : Black

MS ERW C-Class Heavy Pipe Cap

Price 50.0 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Surface Finish : Smooth

Material : MS

Color : Black

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry