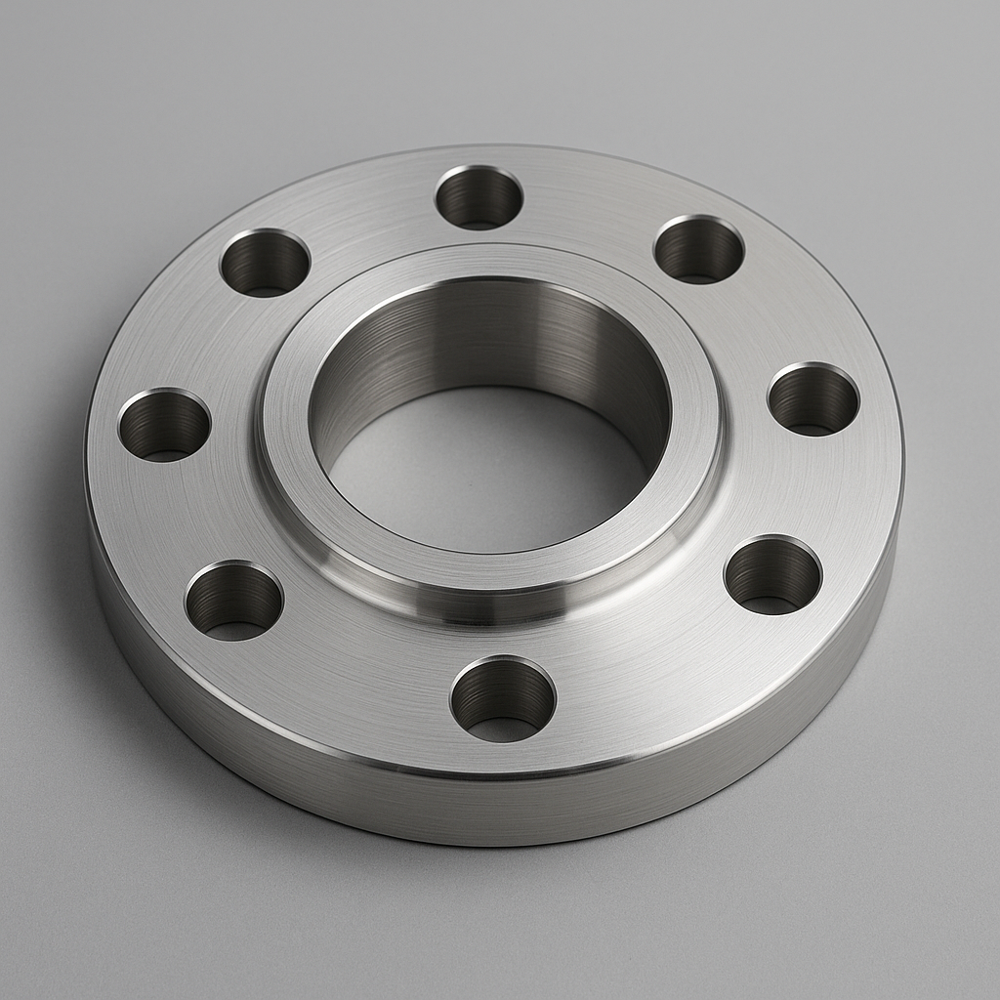

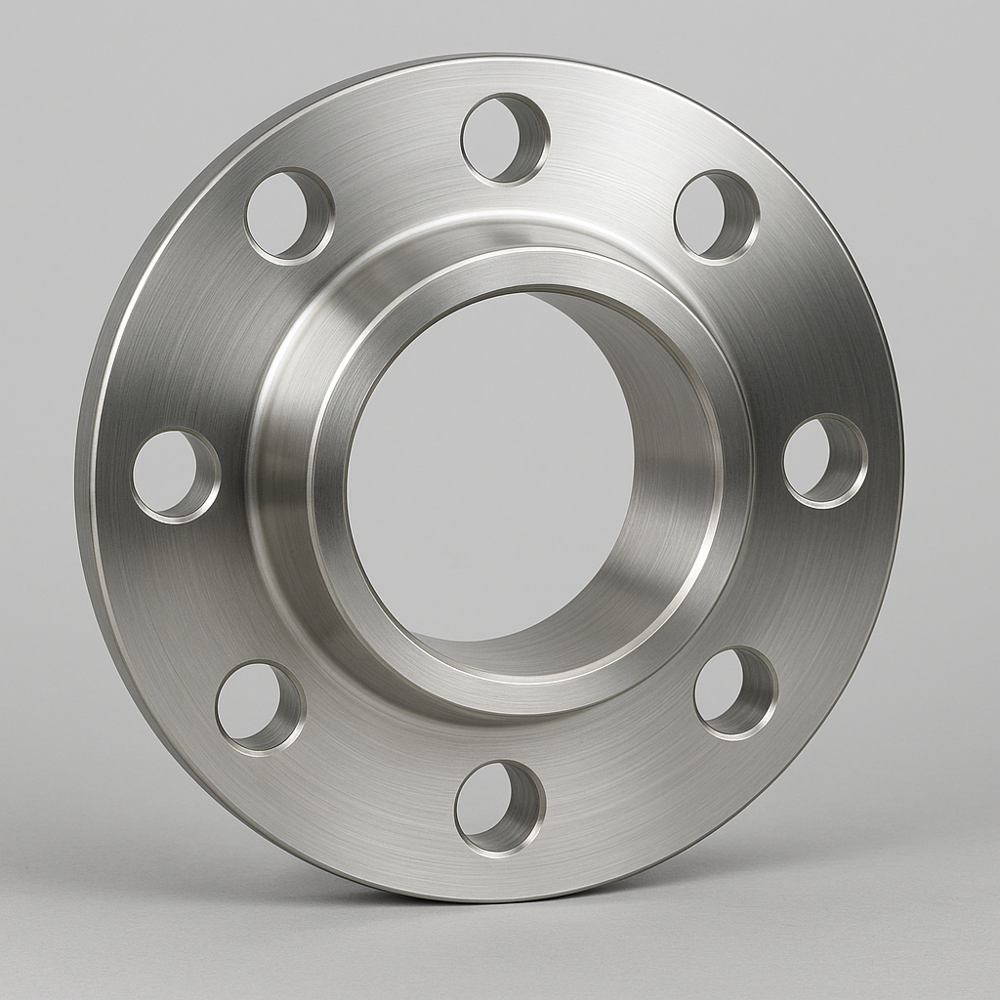

SS Flanges

Price 110 INR/ Unit

SS Flanges Specification

- Features

- High Quality

- Shape

- Round

- Usage

- Industrial, Etc

- Working Presssure

- High

- Material

- Steel

- Surface

- Galvanized

- Size

- Standard

- Color

- Silver

SS Flanges Trade Information

- Minimum Order Quantity

- 100 Units

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 7 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About SS Flanges

Stainless steel (SS) flanges are typically manufactured from austenitic stainless steel alloys most commonly grades304 and316 whose corrosion resistance and mechanical properties derive from their precise chemical compositions. Below is a summary of the key alloying elements and their typical weight percent ranges for these two grades:

| Element | SS304 (%wt) | SS316 (%wt) |

|---|---|---|

| Carbon (C) | 0.08Wikipedia | 0.08upmet.com |

| Manganese (Mn) | 2.00Wikipedia | 2.00upmet.com |

| Silicon (Si) | 1.00Wikipedia | 0.75upmet.com |

| Phosphorus (P) | 0.045Wikipedia | 0.045upmet.com |

| Sulfur (S) | 0.030Wikipedia | 0.030upmet.com |

| Chromium (Cr) | 18.0 20.0Wikipedia | 16.0 18.0upmet.com |

| Nickel (Ni) | 8.0 11.0Wikipedia | 10.0 14.0upmet.com |

| Molybdenum (Mo) | 2.0 3.0upmet.com | |

| Nitrogen (N) | 0.10upmet.com | |

| Iron (Fe) | Balance | Balanceupmet.com |

-

Grade304 ("18/8 stainless steel) is the most widely used SS flange material, valued for its general purpose corrosion resistance and formability .

-

Grade316 adds molybdenum for enhanced resistance to chlorides and marine environments, making it preferable for more aggressive service conditions

-

Minor elements (P, S, Si, Mn, N) are controlled to low maximum levels to optimize corrosion resistance and weldability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Flanges Category

SS 316 Stainless Steel Flanges

Price 480.0 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Good Quality

Surface Finish : Smooth

Usage : Industrial

Material : SS

Blind Flange

Price 1200 INR / Kilograms

Minimum Order Quantity : 1 Number

Features : Good Quality

Surface Finish : Smooth

Usage : Industrial

Material : SS

SS 304 Stainless Steel Flanges

Price 38 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Good Quality

Surface Finish : Smooth

Usage : Industrial

Material : SS

Corrosion Resistant Stainless Steel Flanges

Price 110 INR / Piece

Minimum Order Quantity : 100 Pieces

Features : Durable

Surface Finish : Finished Polished

Usage : Industrial

Material : Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry