Raised Face Flanges

Price 90 INR/ Piece

Raised Face Flanges Specification

- Features

- Easy to use

- Application

- Industrial

- Fittings

- Flanges

- Material

- Mild Steel

- Shape

- Round

- Surface

- Other

- Pressure

- 2500 PSI

- Size

- 1/2 inch to 48 inches

- Color

- Silver

Raised Face Flanges Trade Information

- Minimum Order Quantity

- 100 Pieces

- FOB Port

- nhava sheva

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 2 Days

- Sample Available

- No

- Sample Policy

- Within a certain price range free samples are available

- Main Export Market(s)

- Western Europe, Africa, Middle East, North America, Eastern Europe, Central America, South America, Australia, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015, IBR Approval, Mill Test Certificate (MTC), Third-Party Inspection (on request)

About Raised Face Flanges

Raised face flanges are defined by their face geometry rather than by a unique alloy in practice they re made from the same base materials as other flanges. The most common grades and their typical chemical compositions are:

-

Carbon steel raised face flanges (ASTMA105)

Same as "Custom Flanges per ASTMA105:-

C 0.35%

-

Mn0.60 1.05%

-

P 0.035%

-

S 0.040%

-

Si0.10 0.35%

-

Cu, Ni 0.40% each

-

Cr 0.30%, Mo 0.12%, V 0.08%

-

Febalance

-

-

Stainless steel raised face flanges (ASTMA182 F304 & F316)

Element F304 (%wt) F316 (%wt) Carbon (C) 0.08 0.08 Manganese (Mn) 2.00 2.00 Silicon (Si) 1.00 1.00 Phosphorus (P) 0.045 0.045 Sulfur (S) 0.030 0.030 Chromium (Cr) 18.0 20.0 16.0 18.0 Nickel (Ni) 8.0 12.0 10.0 14.0 Molybdenum (Mo) 2.0 3.0 Nitrogen (N) 0.10 Iron (Fe) Balance Balance -

ASTMA182F304 ("304SS ): the 18%Cr 8%Ni austenitic alloy for general purpose service

-

ASTMA182F316 ("316SS ): adds Mo for superior chloride stress corrosion resistance in harsher environments

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Specialty Flanges Category

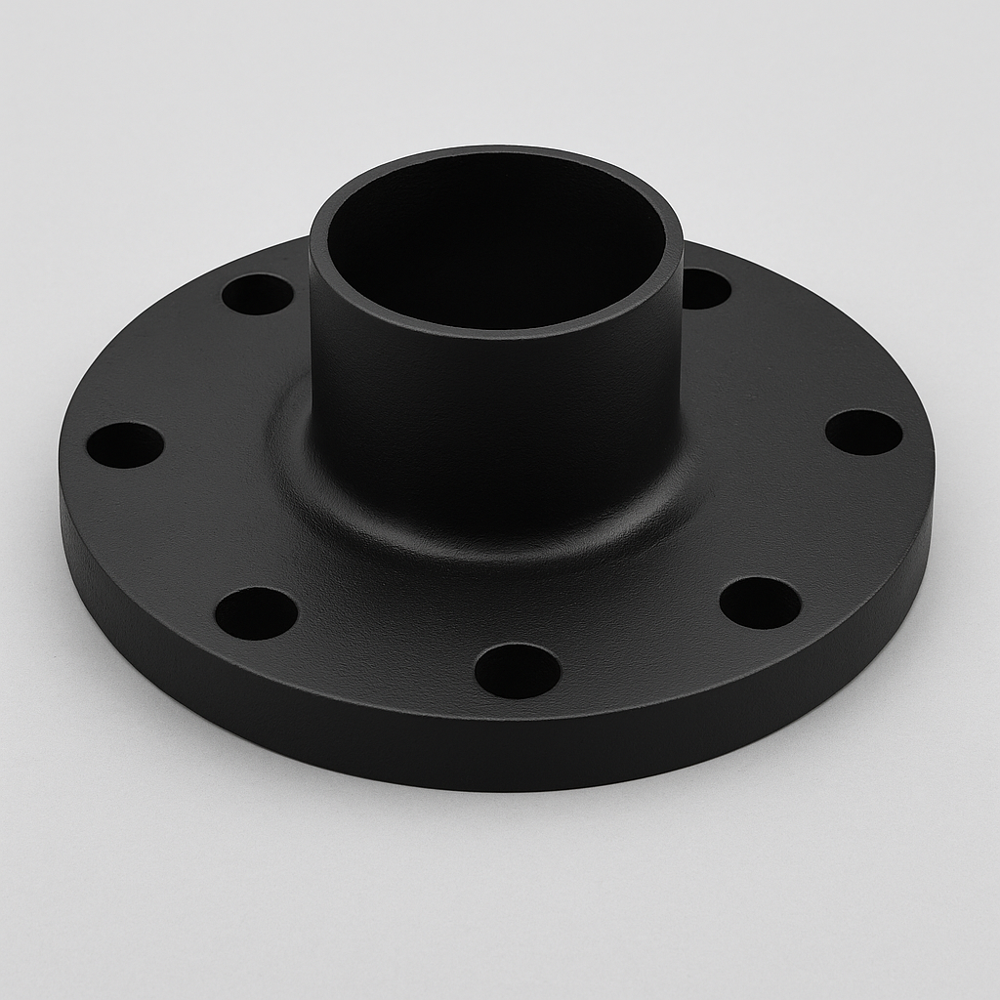

Puddle Flanges

Price 500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : SS

Shape : Round

Color : Black

Application : Construction

Threaded Flanges

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Mild Steel

Shape : Round

Color : Silver

Application : Industrial

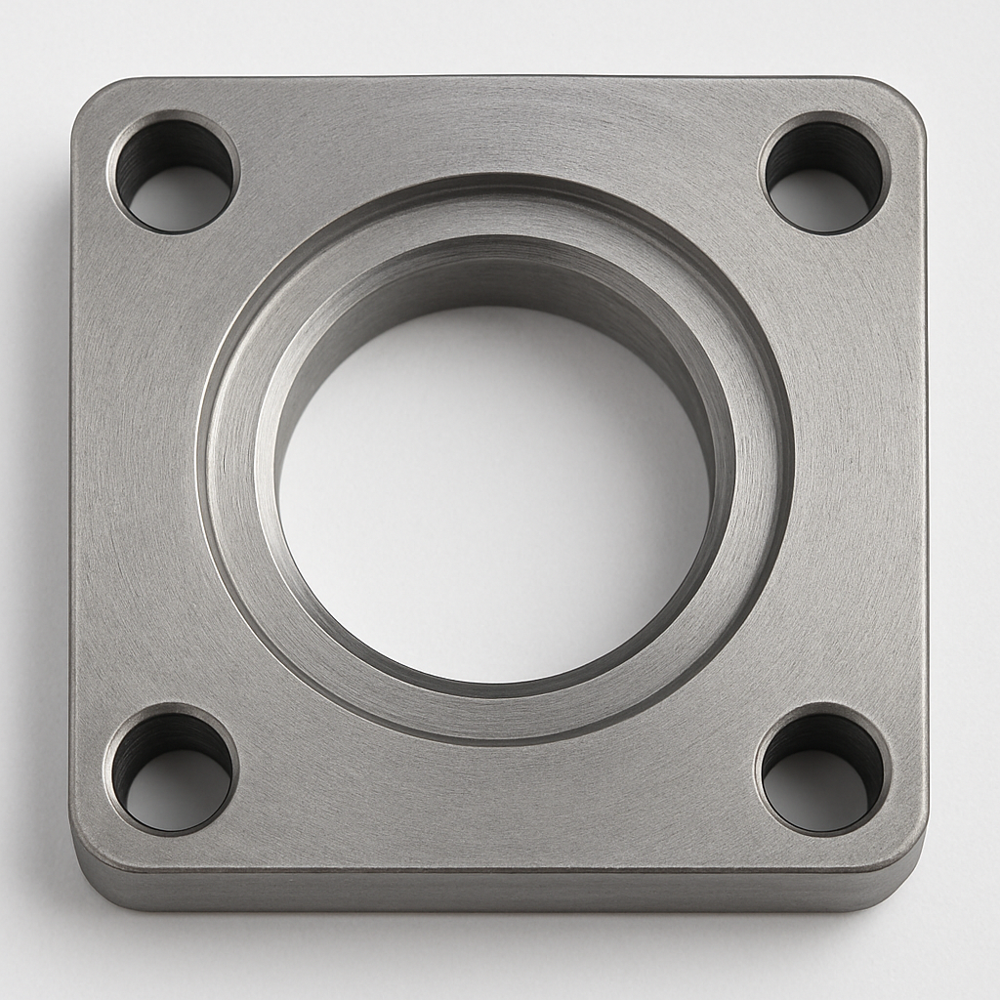

Square Flange

Price 160.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : SS

Shape : Square

Color : Silver

RTJ Flanges

Price 120 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Mild Steel

Shape : Round

Color : Silver

Application : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry